After using a 3D printer, you will inevitably eventually come across the filament clogging in the extruder. This can ruin prints, however, luckily is easy to fix. If you have a 1.25mm J-hook this will work best, alternatively you can use a straightened paper clip.

1. Ensure the 3D printer is off and unplugged before beginning this process. Make sure to have the paperclip at the ready.

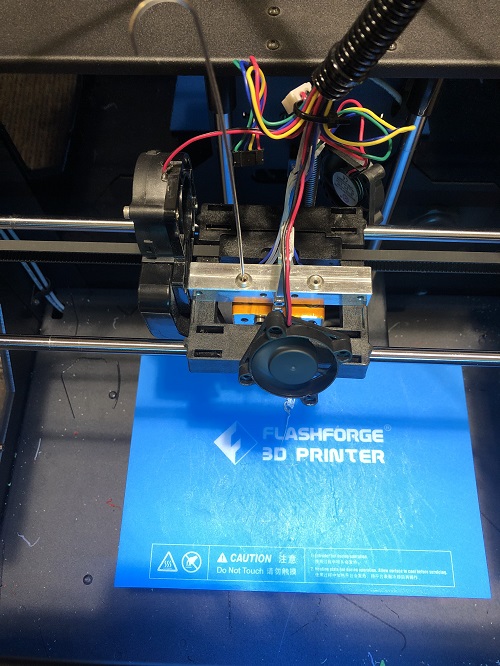

2. Depending on the printer, remove the feeder first. This is done on most printers by unscrewing the two screws on the front of the fans, pulling off the fan guard, fan, heat sink, and spacers. For PowerSpec printers there is a small spacer in the screw hole on the fans, as well as a larger spacer between the heatsink and fan. Keep in mind which side which fan is on, as this is important to place back on correctly.

3. Once the feeder is removed, access is granted to the extruders. They are mounted on a small metal bar, however the extruders do not need to be removed from that.

4. If there is filament stuck directly into the extruders, the extruders need to heat up in order to remove the filament. Please keep in mind the extruders themselves will be very hot and it is important to keep fingers and other components away from them. The fans will automatically turn on once the extruders reach a certain temperature.

5. Allow the extruders to heat for roughly 5-10 minutes, depending on how badly they are clogged.

6. Take the j-hook and insert it into the extruder to push the filament out.

7. Continue pushing the filament out until little or no filament sticks to the j-hook after pulling it out.

8. Shut the printer off and let it cool before assembling it back.

9. Once the printer is reassembled, load more filament and continue printing.