Your Own Maker Space At Home

-Andy Leer (Merchandise Manager for Maker Boards/3D Printing)

It’s never been easier to create your own at-home maker space. Not only is it becoming more accessible for new-comers and novices, but desktop digital fabrication machines have lowered in price over the last 10 years. In 2013, companies like Printrbot were offering a Barebones 3D Printer Kit for $199. Now, in 2022, Micro Center offers new retail store customers a $99 coupon for the popular Ender 3 Pro. Access to these idea-inspiring tools has become more affordable.

It’s not uncommon to find a hobbyist with multiple 3D Printers in their homes, and more and more people are gaining access to smaller CNC machines and hobby lasers. These machines often act as a gateway into a small home business and are eventually upgraded to larger, more prosumer or industrial-grade machines.

Home-grade tools include 3D Printers, desktop CNC, hobby lasers, vinyl cutters, and even CNC embroidery machines. All of which can be purchased for $200-$500 per machine. This low cost makes having a multi-faceted Maker space at home much more of a reality for many people.

Access At An Early Age

Over the past decade, schools, libraries, and community-based Maker spaces have increased public access to digital fabrication tools. Incorporating digital fab education in the classroom has increased knowledge and utilization among children in grades K-12. For students with a propensity for operating and designing with these machines, the reduced cost, and increased availability have helped move these machines into homes.

Safety First

Whether it’s the needle of a sewing machine, the beam of a 10watt diode laser, or the high RPM spinning bit of a CNC machine, safety should always be a top consideration. It is always important to follow common sense and manufacturers' recommendations when using these automated tools. It is also important to consider any by-products when transforming your materials.

Lasers, for instance, often create smoke from whatever it is engraving or cutting. Beyond evacuating the smoke, it is essential to understand what materials may off-put hazardous gas when burnt. You can find this information in online product safety sheets and manufacturers' recommended materials.

Generally, any time you’re running any machine that utilizes heat or generates dust, it is recommended that you’re in an area with ample ventilation and fresh air.

It is vital to ensure your project is secure to your machine when operating CNC machines. More importantly, never touch the device during actual operation.

It is important to remember that a 3D printer nozzle and bed require high operating temperatures that can easily burn skin. Also, good ventilation is recommended with 3D printing as well.

The Tools of the Trade

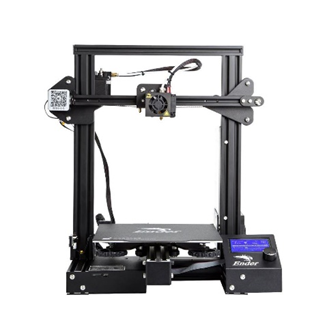

Entry-level 3D Printers have come a long way from the machines of the late 2000s. With consistency in build quality as well as improvements in software and consumables, it’s easier to find success printing sooner with an entry-level machine such as the Creality Ender 3 Pro than it was even a few years ago. While there is still some assembly required, which allows the manufacturer to keep the cost down, the sheer number of how-to videos and users on the internet has increased this entry-level printer's success and adoption rate. While it might not be the most flashy or powerful, it still stands as a solid entry-level machine.

Laser engravers such as the Totem S from Two Trees Tech have pushed the boundary in what a sub $500 laser can do. Basic engraving on materials such as wood, acrylic, and even anodized aluminum allows this diode-based laser to punch above its weight class. Previously, CO2-powered lasers, even in the hobby range with a respectable bed size, would cost you over $1,000 and would often require external water cooling for the laser tube containing the CO2 gas. These newer diode lasers continue to push their way towards the power of those entry-level CO2 lasers at a fraction of the cost. Additionally, laser rotary stages can be added to allow the engraving of cylindrical objects such as glassware and coffee mugs.

Two Trees also makes a desktop CNC machine in the 3018 (30cm x 18cm bed size) class that currently comes in at a sub $200 price point. These desktop machines are great for milling softer materials and working their way up to aluminum. Many folks use these smaller machines for applications like milling circuit boards, creating jewelry, and customizing existing products.

With these affordable single-use maker tools also come machines that can perform multiple functions. The Snap Maker 2.0 Modular 3 in 1 (A350) can not only 3D print but also laser engrave and utilize a CNC spindle for use with milling bits. These all-in-one machines can benefit people who are limited on space and don't require multiple processes to be run simultaneously. Because many of these machines utilize the same movement style, there are add-ons for some machines listed above to give them multiple functions, such as laser or CNC.

Software - Free to Tinker

One of the most significant barriers to entry in the past had been having the correct software. Customers often paid a premium for software, and ultimately the software was clunky at best. Machines that shined in the earlier days were often more expensive due to the time and development that went into the machine and the software. That is no longer the case. And while there are still many excellent software suites that require either a subscription or upfront cost, many low-cost or free alternatives have matured to being quite user-friendly and compatible with many machines.

It is important to understand the software toolchain for these devices. It often starts with a CAD/CAM (computer-aided design or modeling). This piece of software is where you often design the project from scratch. This is often the best way to go when trying to recreate a mechanical project vs. attempting lower-end 3D scanning devices. Software such as Autodesk Fusion is a very powerful CAD/CAM package that allows you to create designs. And while it started as free, it now has monthly costs associated. Other tools such as Shapr3D allow for modeling cross-platform on Windows/Mac and iOS, which can be handy is also a subscription-based option. For free, more basic modeling, users can start with Tinkercad.com, also by Autodesk. This user-friendly online application allows users to explore 3D modeling, albeit with many limitations, but in a creative and approachable manner.

Many people are now using the powerful and relatively inexpensive LightBurn software for lasers. This competes with many higher-priced laser software alternatives. LightBurn is continually improved, and features support for many inexpensive lasers, including the aforementioned Two Trees Totem S. This software allows you to design and send commands to the laser for operation.

Similarly, for CNC, easel.inventables.com allows you to design and run your desktop CNC machine. While some of this is open and free for initial use, there is now a subscription-based model.

Many alternatives exist with varying degrees of ease of use and cost. However, it is normally safe to expect that your machine, be it a laser, CNC, or 3D printer, will include software on a SD/micro SD card to operate or create your designs.

If you are not currently ready to create your designs and want to start operating your machine, sites like thingiverse.com, Printables.com, and instructables.com are excellent places to look for free designs uploaded by other site users.

Environmental Considerations

Now that you’ve got your machines and software, and are ready to start producing your next-world-changing ideas, here are a few last things you’ll want to consider when setting up your space. You’ll want to make sure you have ample power to run these machines. While they are not as power-hungry as their more industrial counterparts, you may run into issues if you’re operating them on a similar circuit to your everyday items, such as desktop computers and larger appliances. A few 3D Printers can pull a lot of wattage when they get up to heat and are running simultaneously.

It is also important to have ample lighting in your environment. Operating and maintaining the machines will be much easier if you can see what you’re doing. The temperature of your environment can also play a big part in the success of your output. 3D printers need to maintain heat on the hot end and the bed. Cold, drafty spaces may affect your ability to print consistently. Humidity can also play a factor in consumables such as filament and wood.

It may seem obvious, but access to an internet connection or Wi-Fi may be necessary as some machines can be controlled via an app or an online software, such as the case with easel by inventables and designing in tinkercad.com.

What are you going to make?

With all of the affordable options for digital fabrication at your fingertips, what will you make? Take it one step at a time. Every chance you get to run a job or print a widget is another chance to learn and take your maker abilities to the next level. As always, check out www.Microcenter.com for all of our options to build out your Maker space at home.

Looking for more Maker guides and reviews?

We’ve got a 3D Printing Community as well as a Maker Community, a whole section of 3D Printing How-Tos, as well as articles on How to Choose a 3D Printer and Raspberry Pi set-up guides. And if you can’t find what you’re looking for, don’t hesitate to post a new discussion and the Community will be happy to help!

Comments

-

My Dad was an Industrial Arts (Shop) teacher so I grew up building things from nothing for years, it lead me into architecture school eventually getting a Bachelor of Architecture. I think about how spoiled I was to always have access to a complete workshop not only at home but also where he taught school. I learned drafting from him, how to use power tools, how to do simple to complex repairs on a regular basis. A skill set that is so rewarding. The Maker Space is a cousin to the old wood shop and the technology is accessible enough that others can get a start much like I did years ago.

-

I bought an Ender 3 V2 a little over a year ago, built it, but never got around to actually plugging it in and using it. Perhaps that's something I should do sometime soon.

Categories

- All Categories

- 1 The Blog

- 1 What's Trending

- 7.9K The Community

- 3.2K General Discussion

- 144 New Members

- 870 Consumer Tech

- 233 Prebuilt PCs and Laptops

- 167 Software

- 33 Audio/Visual

- 54 Networking & Security

- 4 Home Automation

- 5 Digital Photography

- 14 Content Creators

- 30 Hobby Boards & Projects

- 84 3D Printing

- 83 Retro Arcade/Gaming

- 62 All Other Tech

- 423 PowerSpec

- 2.6K Store Information and Policy

- 150 Off Topic

- 61 Community Ideas & Feedback

- 615 Your Completed Builds

- 4K Build-Your-Own PC

- 2.9K Help Choosing Parts

- 328 Graphics Cards

- 335 CPUs, Memory, and Motherboards

- 145 Cases and Power Supplies

- 54 Air and Liquid Cooling

- 49 Monitors and Displays

- 93 Peripherals

- 68 All Other Parts

- 65 Featured Categories

We love seeing what our customers build

Submit photos and a description of your PC to our build showcase

Submit NowLooking for a little inspiration?

See other custom PC builds and get some ideas for what can be done

View Build ShowcaseSAME DAY CUSTOM BUILD SERVICE

If You Can Dream it, We Can Build it.

Services starting at $149.99